As soon as the microorganisms are transferred from one individual to another, the risk of an infection spikes. These microbes, if pathogenic, result in the initiation of different diseases which then require medical attention to treat. Therefore, if this transfer is controlled and minimized, the spread of diseases could be contained. A way to do so is the implementation of thorough cleaning and disinfection measures which produce bactericidal effects and reduce the chances of infections. Let us explore the latest advancements in disinfection supplies that can be employed for this purpose.

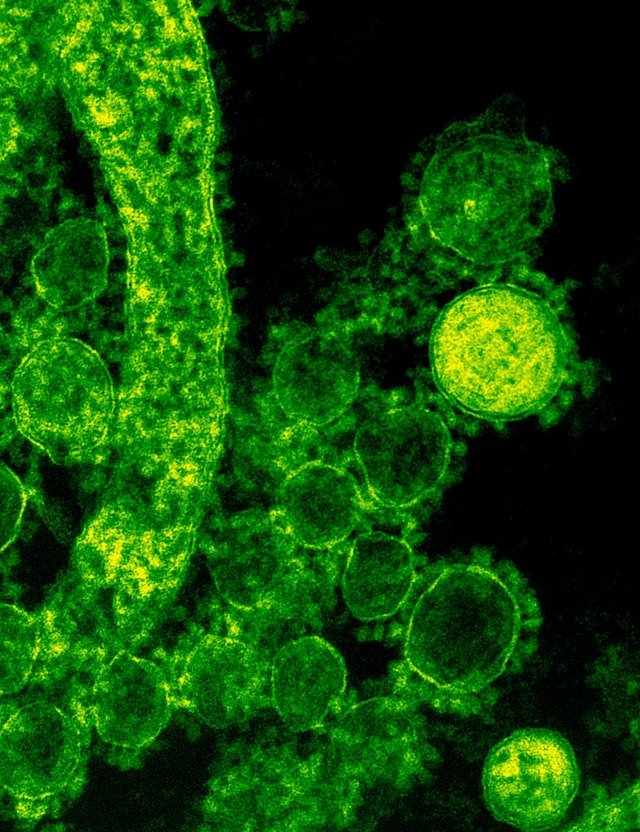

Visualization of microorganisms under the microscope

Characteristics of a good disinfectant

Among many disinfectants available in the market, there is a wide range of products that differ from each other based on their features such as residual time or spectrum of activity, etc. Therefore, it is important to have a basic understanding of the qualities of a good disinfectant which have been listed below:

· A broad spectrum of bactericidal activity:

A good disinfectant should depict bactericidal activity against multiple types of bacteria. This helps eliminate the need to use more than one chemical agent to achieve complete disinfection.

· High environmental compatibility:

A disinfectant should be eco-friendly as well as sustainable. Its chemical nature should neither interfere with the environment nor impact the biotic components of an ecosystem.

· Rapidly acting formulations:

The formulation that carries the disinfectant should be quick in action. Moreover, its contact time must be minimal. This feature enhances the disinfectant activity of the product.

· Increased residual efficiency:

Higher residual efficacy ensures that a disinfectant keeps on doing its job for a longer period of time after a single use thus eliminating the need for multiple applications.

· Novel delivery systems:

Newer delivery systems such as controlled release or target-specific formulations increase the disinfectant efficacy and penetration. Moreover, a disinfectant becomes more stable when formulated in these kind of formulations.

Evaluation of bioburden using laboratory tests

Latest innovations in medical cleaning and disinfection supplies

Latest developments are being made in order to minimize the chances of contamination, particularly in healthcare facilities where contracting an infection is easiest. To achieve this aim, multiple cleaning technologies are being designed and tested. Moreover, several monitoring methods are also being devised to check the accuracy of cleaning. Some of the latest ones are as follows:

1. Novel cleaning technologies

Many new methods of thorough cleaning have been reported all of which compete to be declared as best based on the extent of bactericidal activity they provide. These methods, although efficient and easy to implement, vary in certain parameters. These methods include the following:

· Room cleaning robots

The employment of robots to disinfect rooms in a healthcare facility has provided a touchless cleaning method that not only saves time but also significantly reduces bioburden. These robotic systems work by releasing germicidal solutions in the form of vapors or aerosols of hydrogen peroxide.

Moreover, UV radiation can also be emitted from such devices. Keeping in mind the toxic effects of hydrogen peroxide as well as UV rays on living organisms, these methods can only be employed in empty rooms. Demerits of these processes include the cost which is high at this point and needs to be adjusted.

· Antimicrobial surfaces

Surfaces that do not accumulate high concentrations of bioburden are being established. In this regard, the material of choice that is used to coat the surfaces in a hospital is copper. This choice has been made based on the evidence that a property of bacterial resistance exists in the metal which, however, has not been fully supported by the research literature.

Therefore, there is a need to check the efficacy of copper. Moreover, the overall cost of the project is very high as all the surfaces in a healthcare facility need to be lined with copper sheets. Nonetheless, the technology is in the pre-clinical phase and needs further testing to get FDA approval before marketing.

· Antibacterial textile materials

Certain types of textile materials are being employed for making hospital scrubs as well as curtains and bed sheets. These materials are claimed to be antimicrobial in nature. Textiles made up of silver or quaternary ammonium-impregnated provider scrubs have been proven to be the most effective items in this category.

Trained personnel disinfecting the surfaces

2. Monitoring of disinfection – Surrogates of contamination

When a surface has been cleaned and disinfected, it is essential to evaluate the level of cleanliness. Surrogate markers including adenosine triphosphate (ATP) levels and fluorescent markers help to do so. Let us discuss how they work.

· Adenosine triphosphate

Organic load on a surface is quantified using ATP levels which, in turn, indicate the extent of cleanliness of a surface. Living bacterial cells produce ATP which can easily be quantified. If a surface has a higher ATP value, there is an indication that a huge number of living cells are present on it. Therefore, after the employment of a cleaning method, the level of ATP is checked. If it gives minimum value, it can be manifested that the cleaning method is efficient.

· Fluorescent markers

Similarly, before starting the cleaning process, fluorescent markers are placed on the surface. Once the cleaning has been completed, the level of these markers which are still retained on the surface is analyzed quantitatively. Technically, no fluorescent marker should be left behind as manual cleaning has the capability to remove them completely.

Conclusion

Keeping the surfaces, along with the equipment, clean and germ-free is one of the main goals of a healthcare facility. If not taken care of, these equipment as well as other items could transfer multiple infections to several patients thus becoming responsible for the boom in disease cases.

Therefore, guidelines have been established by every healthcare setup to minimize their bioburden. In this regard, novel technologies are being introduced that work in terms of cleaning as well as monitoring the level of microbes. Although there is a need for further studies to confirm their efficacy, these latest technologies are indeed the future of healthcare.

PhD Scholar (Pharmaceutics), MPhil (Pharmaceutics), Pharm D, B. Sc.

Uzma Zafar is a dedicated and highly motivated pharmaceutical professional currently pursuing her PhD in Pharmaceutics at the Punjab University College of Pharmacy, University of the Punjab. With a comprehensive academic and research background, Uzma has consistently excelled in her studies, securing first division throughout her educational journey.

Uzma’s passion for the pharmaceutical field is evident from her active engagement during her Doctor of Pharmacy (Pharm.D) program, where she not only mastered industrial techniques and clinical case studies but also delved into marketing strategies and management skills.

Throughout her career, Uzma has actively contributed to the pharmaceutical sciences, with specific research on suspension formulation and Hepatitis C risk factors and side effects. Additionally, Uzma has lent her expertise to review and fact-check articles for the Health Supply 770 blog, ensuring the accuracy and reliability of the information presented.

As she continues her PhD, expected to complete in 2025, Uzma is eager to contribute further to the field by combining her deep knowledge of pharmaceutics with real-world applications to meet global professional standards and challenges.